A ballast is an electrical device used to stabilize the current in fluorescent lighting, cathode ray tubes, and thermionic vacuum tube devices.

An AC voltage applied across an inductor may result in a higher current than the same voltage applied across an ideal capacitor of the same value. The relationship between these parameters can be described using equations derived from electromagnetic theory.

The simplest form of ballast is a resistor placed in series with the lamp to limit current flow through it, this also limits power loss in heating elements like incandescent lamps operating on direct current (DC). For example, for optimum operation of a certain size and type of lamp, its characteristic curve may indicate that at 200 V DC input it draws 10 A, but a particular design may only operate properly when the voltage drop is let across a 13 Ω resistor, equivalent to a power loss of about 8 W. The simplest ballast for fluorescent lamps to operate on AC power operates simply as an inductive reactance with no resistance, this ballast limits current by inducing an opposing alternating current in the lamp, which produces resistance within it, but does not dissipate energy or produce heat.

What is an Electrical Ballast?

An electrical ballast is a device that operates in series with a load to limit the amount of current flowing through an electrical circuit. The inductive ballast used in fluorescent lamps, for example, is a well-known and widely utilized illustration of this principle.

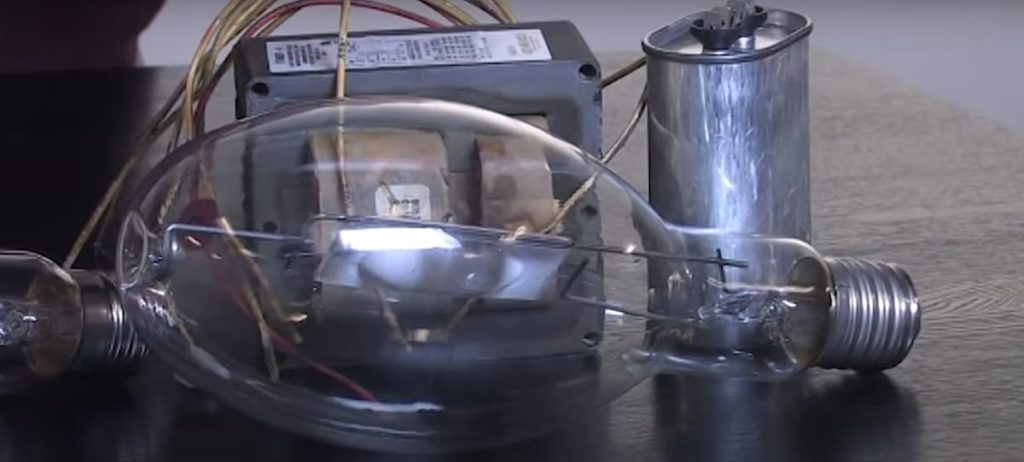

Ballasts can range from extremely simple to extremely complex. They might be as basic as a resistor, inductor, or capacitor (or a combination of these) connected in series with the lamp, or as complicated as compact fluorescent light ballast and high-intensity discharge light ballast Electronic ballasts are offered for use with both types of lamps vary considerably in complexity.

What does an Electronic Ballast Do?

An electronic ballast operates a fluorescent light bulb at a higher frequency than the power line, increasing the lamp life and providing an almost-pure DC supply to the bulb. Electronic ballasts also reduce flicker in sensitive electronics such as computer monitors which use fluorescent lights for backlighting. These ballasts often contain mercury (Hg), however, new “green” or “halogen cycle” ballasts are available that do not.

Types of Electronic Ballast

Electronic ballast may take on many forms, there are adjustable-voltage low voltage, high voltage, electronic, magnetic, electromagnetic (or inductive), piezoelectric or ceramics. Adjustable-voltage low voltage and high voltage are most widely used for low voltage lighting systems. Electronic ballasts are found across a wide range of applications from automotive lighting, to residential and commercial spaces, they are most popular in high-intensity discharge lamps that require more complicated regulation than the simple voltage/resistance regulation common in magnetic ballasts.

Fluorescent luminaires usually include integral electronic equipment (ballasts) to limit the starting surge and regulate the operating potential and light output. These may be combined into one compact unit that fits into the space formerly occupied by an incandescent reflector spotlight or globe. The most common type of magnetic ballasts used in fluorescent lighting may contain either one or two windings.

Current Limiting Magnetic Ballast

Current limiting magnetic ballasts can also be designed to operate mercury vapour high-pressure sodium lamps, metal halide high-pressure sodium lamps, and other low voltage discharge light sources if the inductance of the ballast is capable of withstanding the arc voltage developed when starting these types of lamps. All current-limiting ballasts for magnetic induction type lamps require an electronic starter to start them initially, afterwards, they do not draw any operating current.

High-power striking transformers are heavy steel blocks in which a large number of turns of heavy gauge wire are wound around a thick laminated iron core that serves both as an energy storage device (energy induced into it by the alternating current (AC) supply is released as a pulsating high voltage and low current) and as the primary winding of the ballast (the AC power system is connected to this winding).

The AC voltage across the primary winding induces an AC voltage in the smaller secondary winding by electromagnetic induction. This induced voltage has a polarity such that it adds to (and thus sustains) the primary voltage. As such, if both ends of the ballast’s primary are open, no current may flow through either end of its secondary, however, any load resistance connected between those two ends may be part of a circuit including the ballast’s primary and secondary windings and thus dissipate energy (heat) continuously. Some types use shunt capacitors instead of series inductors.

How to Achieve a Full Rated Light Output from a Fluorescent Lamp Light Fixture

Any fluorescent lamp light fixture using a magnetic ballast is normally purchased with the necessary ballast for full rated lamp operation. However, if loads are changed or additional fixtures are being added, it may be necessary to change the existing ballast to one of greater capacity. This may be done by first determining what type of magnetic ballast is used and then finding one that may produce the necessary output at the input frequency and voltage provided.

Electronic high-frequency ballasts for fluorescent lamps operate on 60 Hz power but have an internal switching mechanism that operates at 100 kHz or more to boost light output from 40 per cent to 50 per cent (when operated with an A19 lamp). Overheating problems associated with this setpoint may be considered when selecting electronic ballasts.

How to Replace the Electronic Ballast Starter

In some cases, it may be possible to replace a faulty starter with a wire link or series resistor to bypass the bad starter. The resistance could match the operating current of the ballast and provide about 15 W of heat sinking capacity at 28C/50F (8 ohms for 40W ballasts). If a heavy load is placed on the circuit due to shorted tubes or other equipment problems, this repair may not work well since there is no overload protection mechanism available in magnetic ballasts. Thus, it is wise to check all lamps for shorts before going through these steps as they may cause fires or explosions.

If any interior wires are broken or bare wires protrude from an end insulator, these may be repaired or replaced before further use. If the lamps stop operating and the starter is not visible, check for a break or short in one end of either wiring or heating element (a serviceable ballast may still light an individual bad lamp as long as it has some other good lamps to provide starting current). If there is no visible trouble inside the ballast case, proceed as follows.

Check for loose connections at all terminals. A blown fuse located on top of a starter indicates that the safety timer circuit also may have failed. Check this by removing both wires from their receptacles and testing them with an ohmmeter between each wire terminal and case ground. Both readings could be infinite resistance if the timer is good because the safety timer may be closed in order to make the correct contacts.

The Lifetime Expectancy of an Electronic Ballast

The length of time that the electronic ballast may work depends on the quality of the wiring used and its connections, operating temperature, lamp deterioration, overloads, etc. The average life of a magnetic ballast is 20,000 hours at normal room temperatures (approximately 25C/77F) under continuous operation. Ballasts are generally rated for 60 W or 100W lamps so this factor could be taken into account when selecting replacement ballasts. Electronic ballasts, depending on high-quality components and insulation, could last well over 30 years under normal conditions.

Due to the much higher running temperature of electronic ballasts, they are rated for a shorter life than their traditional counterparts. This ballast factor makes them more economical in use since the user may have to buy new ones less frequently. Electronic ballasts usually have longer lives than magnetic ballasts but this is not always true as statistics show. The life of an electronic ballast depends on its initial design and how well it has been engineered. Even if electronic ballasts are designed with extra-long lives, electrical surges or overheating can greatly shorten these lifetimes due to component failure.

The presence of more electronic parts adds some weight to the ballast but the components themselves weigh just a few ounces above that of heavy transformers or inductors. Most ballasts for medium wattage lamps (150W–250W) use either four or six semiconductors plus one power transistor called a MOSFET, while low-wattage units utilize only two semiconductors plus one MOSFET. For these smaller types, heat sinks are usually not required.

How do Light Ballasts Work?

A light ballast contains a circuit that produces alternating current (AC) at high frequency. This can be done by arranging coils of wire in series with the AC power. When one of these circuits is switched on, a magnetic field is produced which may remain as long as it is powered. By placing this coil around another coil or inductive loop, a larger magnetic field may be produced and cause the second coil to produce electricity itself. Fluorescent light and hid lamps works through this lighting ballast. Keep in mind that the ballast factor may affect your fluorescent tubes.

An electronic dimmable ballast works differently from a traditional ballast in order to dim the lamps properly as well as provide overheat protection for both the fixture and lamp. The voltage provided by an electronic ballast varies according to load conditions since it cannot maintain the same constant output as traditional magnetic ballasts do without overheating. High-quality electronic ballasts are able to operate the lamps at approximately 98% of their normal rated voltage when dimming down to 10%. This is not much different from magnetic ballasts which maintain a constant output voltage when dimming.

Electronic ballasts add the third winding in series with the other two windings in order to rectify the current into direct current (DC) for use by the load and inverter circuitry which produces high-frequency AC, usually between 20 kHz to 70 kHz, in order for lamp filaments to properly operate. The high-frequency alternating AC produced by electronic ballasts can be converted back into DC through a process called “phase-cut dimming”. This technique allows the output power to remain constant while the lamp filament is dimmed to reach lower light levels.

Line Voltage and Power Supply in an Electrical Current

Electronic ballasts use thyristors, silicon-controlled rectifiers (SCR), or try to control the flow of current through their tri-phase windings. The starting circuit contains a free-wheel diode which serves as an overcurrent protection device. If the load tries to draw too much current from the ballast, it may short out and open the circuit allowing only a small amount of current through. This prevents any damage to either part in series with this resistor or parts due to overheating, thus making them “fail-safe”.

Top-quality electronic ballasts are provided with overheat cutouts that usually consist of two SCRs connected back-to-back inside the case of the ballast, which is wired in parallel with one another. When either half-bridge circuit senses an overheat condition, it opens and interrupts the current to that half of the windings. This renders the ballast completely inoperative until it cools down enough for both circuits to close normally again. If these SCRs have failed then they may need to be replaced along with any other parts connected in series with them or any parts connected between where they cut out and ground on either side of the load.

High-frequency electronic ballasts usually use thyristors because they switch so fast compared to line voltage power frequency AC (50 Hz or 60 Hz). These components are capable of switching up to 36 kHz without generating noise in the line voltage current which is harmful to other equipment. Since they switch so fast, there are no magnetic field emissions associated with them. They also require less capacitance than SCRs and thyristors to produce an equivalent amount of high-frequency AC.